Product Description

Product Description:

DN series motor is two speed electromagnetic brake motors we designed for European style electric hoist lifting.

1. Motor Features:

1.1 Motor housing is made of aluminum, beautiful appearance, excellent heat elimination.

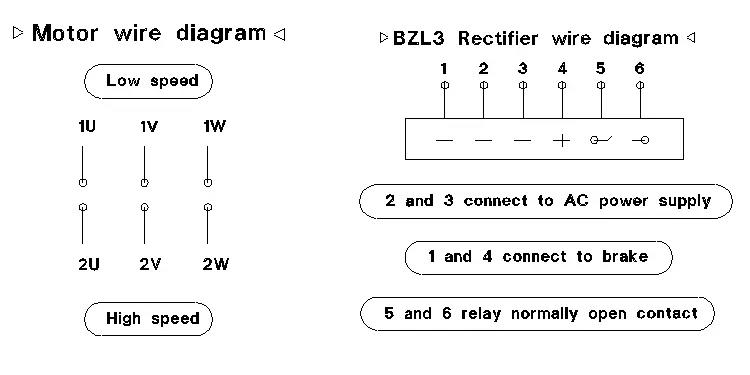

1.2 Motor stator adopts dual winding and two-speed, 6 lead wires, motor with a constant torque speed adjusting, adjusting ratio is 1: 4, 1: 6.

Slow speed used for machinery start, slowly moving, slowly positioning and braking. Fast speed used for normal lifting.1.3 Motor has a large starting and limit torque, lower starting current, high power density..

1.4 Optimized the smooth performance of the two speed switching, small mechanical shock, strong overload capacity, quiet operation, low noise.

1.5 The motor adopts cylindrical squirrel cage rotor, small size, light weight, simple control, easy maintenance, high reliability.

2. Electromagnetic brake features:

2.1 Electromagnetic brake power supply must be independent, it can not be through the inverter, AC380V half-wave rectification DC170V.

2.2 Brake is with double-sided safe braking. Reliable performance, high closing rate.2.3 Automatic braking when power off, safety braking and without vibration.

2.4 friction plate adopts imported non-asbestos friction plate, less wear, long using life ( approx. one million times braking before the first maintenance)

Operating Conditions:

1. Standard electric system: rated voltage 380V ,rated frequency 50Hz (other voltage and frequency can be customized).

2. Altitude≤1000 meters, -15 ℃≤ ambient temperature ≤40 ℃, relative humidity ≤85%, The working environment should be no explosion dust and non-corrosive.

3. No rain and exposure , outdoor use should be packed with protective cover.

4. Motor should connect ground line, please refer to the power distribution regulations.

5. Please check whether the motor damped or not before using. Use a 500-volt megohmmeter to measure the insulation resistor, the resistor should not be less than 0.5 megohms). Or should dry the motor. The drying temperature should not exceed 80 ℃.

6. Before the motor installed on the device, please make sure the whole system has good and stable operating characters in the unloaded test.

Basic characteristic

1. Protection class: IP54, insulation class: F.

2. Standard working system: fast S3-40%, slow S3-20%.

3. Mounting type: B5.

4. Cooling way: a cooling fan with fully enclosed protect feature (1C411)

5. Adopts electromagnetic power lost brakes. Brake can equip with micro switch (optional), for the protection of the brake, when the brake air gap exceeds the set value, the micro switch will send a signal to the user to adjust the brake air gap, in order to ensure the brakes work normally.

6. The motor winding can use Model MK1 series thermistor (optional) for motor overheating thermal protection. It will be at a closed state when normally and low temperature, it will be at Off state when exceed the set temperature, rated switching temperature is 145 ℃.

Notes: Clients can choose thermal switches, tropical moisture, electromagnetic brake micro-switches, encoders etc. Other items can be customized.

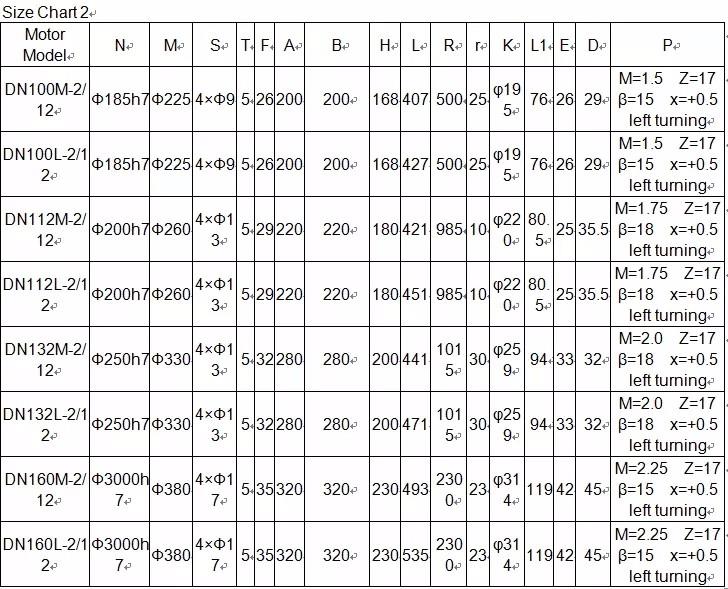

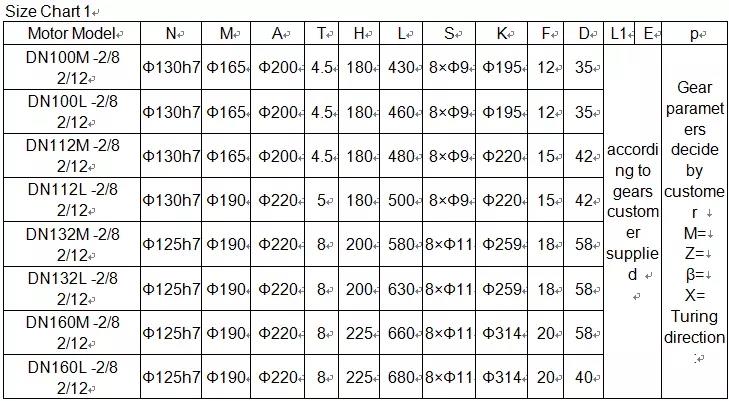

Product Parameters

Motor wiring diagram

Wuhan Vohoboo Import & Export Trade Co., Ltd.

- Phone: +86 027-86790925

- Business Type: Manufacturer

- Location: China

- Main Products: Hoist,crane motor,winch,end carriage,permanent magnetic lifter

- Total Employees:100-500 people

- Year Established:

- Export Markets:

- Total Annual Revenue: