With development and maturity of liquid capsule filling technology, the liquid capsule production technologies have gradually replaced high-cost of soft capsule production technologies. The automatic hard capsule sealing machine is developed for precisely sealing the connection between the cap and the body of hard capsule filled with liquid or solid drug products.The sealer has realized improvement in stablility of drug product by preventing leak from the capsules filled with liquid drugs, preventing oxidation of the drug , it help to improve pharmaceutical physical stability and anti-counterfeiting.

Working principle

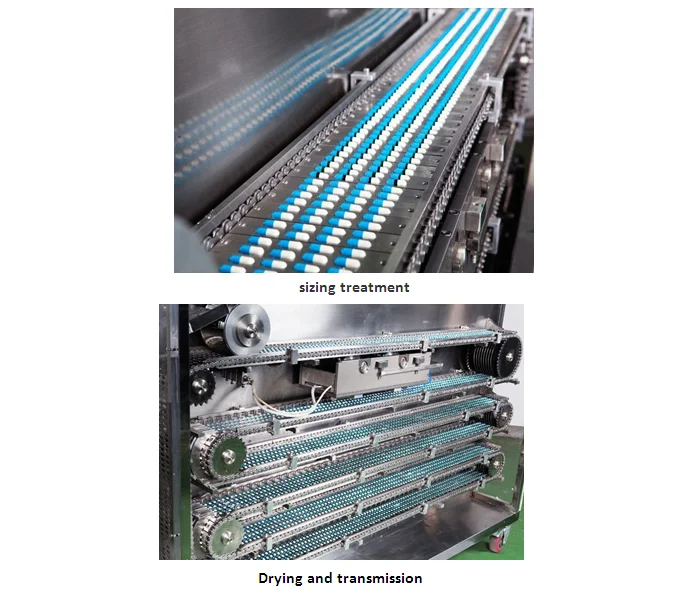

After the hard capsule are baited from hopper, capsule caps and capsule bodies are neatly alignedon conveying mechanism along the same direction by positioning mechanism, after passing through sizing treatment mechanism, connection place of capsule cap and body is automatically coated with safety spill-proof glue(adopting secondary sizing treatment technology to ensure sizing treatment effect) by sizing treatment wheels, then they are naturally solidified in process of conveying mechanism’s reciprocating conveying and after product is dried quickly, then the cap and capsule body be sealed.

Features

1. It with touch screen control, multi-system integrated and high degree of automation.

2. Material-lacking overload is under automatic protection which can ensure material’s smooth supply.

3. Capsule’s feeding, orientation and alignment are accurate and speed can be controlled;

4. Capsule directional, the special designed derctional drum which help to make capsule in directional alignment, and not damage the capsule.

5. Sizing treatment is even and secondary sizing treatment technology make sure good locks sealing effect.

6. Conventional feeding and vacuum feeding are optional in accordance with applicable scene.

7. It adopts highly-sensitive temperature sensor, by which, the emperature of glue box can be real-time controlled.

8. Glue box and machine body adopt separating and closing design, by which, it can be easily disassembled and cleaned.

9. The capsules are drying naturally, it do not need to equip with other drying device. And it not affect the property of the drugs.

10. They are made by stainless steel which conforms to cGMP standard, the part which touch the drugs can be made in ss316 steel.

11. .Its originally created function of capsule chain plate positive and negative conveying can effectively extend conveying distance;

12. It adopts precision pneumatic control system which ensures glue box’s working smoothly up and down , forward and backward.

13. It adopts reciprocating conveying mechanism, it can be naturally dried which does not affect drug properties inside the capsule.

Main working process of Capsule band sealing machines

Capsule Direction and transmission

Wuhan Sinojoinsun Technology & Trade Co., Ltd.

- Phone: +86 027-87635568

- Business Type: Manufacturer

- Location: China

- Main Products: pharmaceutical products

- Total Employees:100-500 people

- Year Established:

- Export Markets:Domestic Market,Asia,Europe

- Total Annual Revenue: